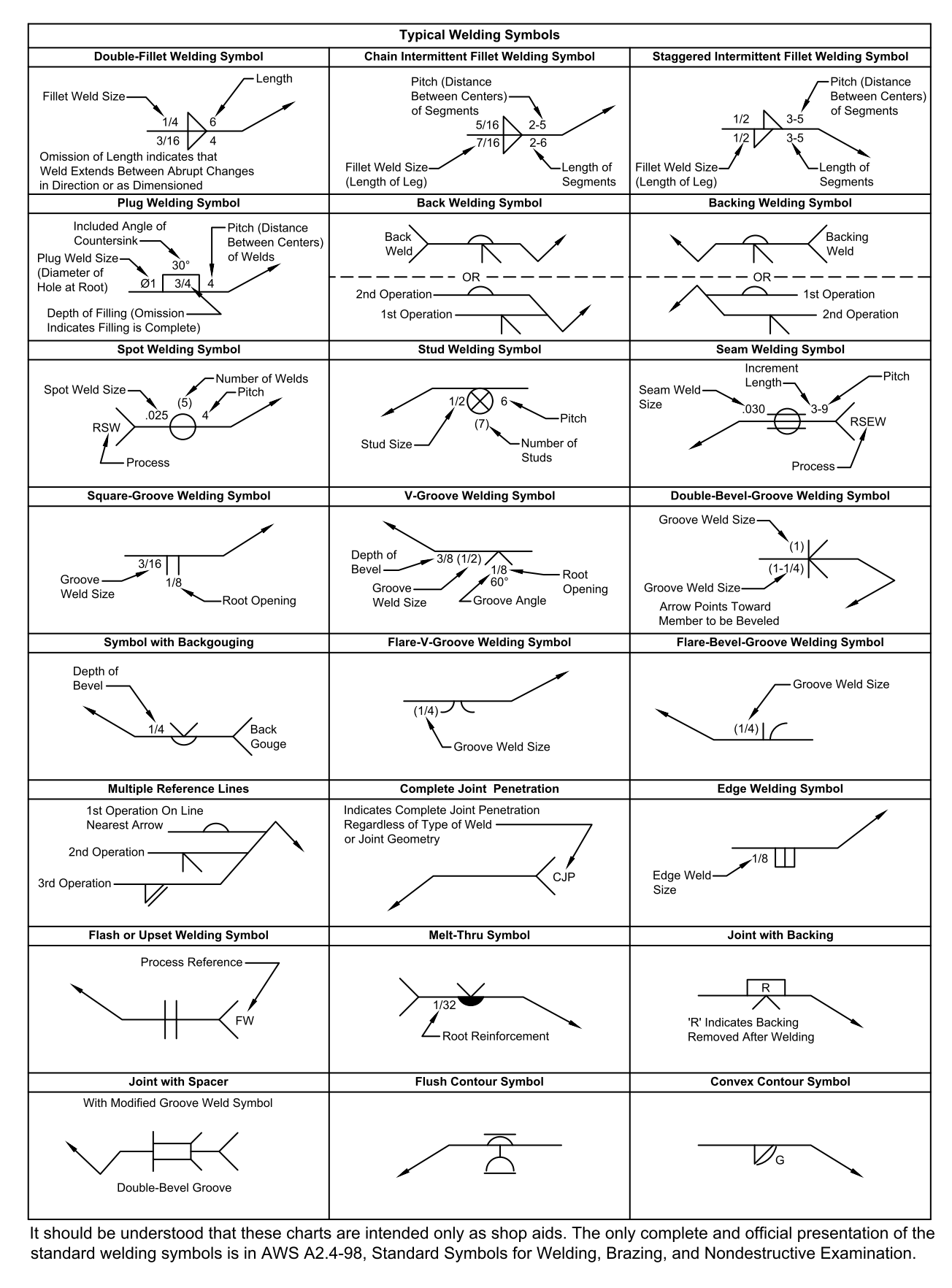

American Welding Society Welding Symbol Chart

American Welding Society Welding Symbol Chart - There are many factors to consider when. A swps is define by aws as a welding procedure specification qualified according to the requirements of aws b2.1/b2.1m, approved by aws, and made available for production welding by companies or individuals other than those. However, this is not always the best option. Selecting the filler metal should not be a trivial matter. This is impossible to detect via weld inspection after welding is complete and very hard to detect while welding. The only difference between the two is that the aws formula includes silicon. The body of knowledge for the cwi exam can be owerwhelming.

The new edition of aws d1.1 structural welding code (steel) has been released. There are many factors to consider when. A swps is define by aws as a welding procedure specification qualified according to the requirements of aws b2.1/b2.1m, approved by aws, and made available for production welding by companies or individuals other than those. These formulas are meant to provide a value for weldability.

The only difference between the two is that the aws formula includes silicon. Welding symbols communicate vital information to the welder. This is impossible to detect via weld inspection after welding is complete and very hard to detect while welding. The main responsibilities of a cwi is to make sure that welding operations are manufacturing products that comply with specified welding codes and. The ability to write and/or interpret welding symbols is essential for many welding industry professionals including welders, supervisors, cwis, welding engineers, estimators, qc personnel and more. It can be easily measured by the use of weld gages.

Typical shielding gases for short circuit transfer include 100% carbon dioxide and mixes containing up to 75% argon with the balance being carbon dioxide. Yet, less than 5% of the customers we consult with have at least a basic understanding of welding symbols. The body of knowledge for the cwi exam can be owerwhelming. A swps is define by aws as a welding procedure specification qualified according to the requirements of aws b2.1/b2.1m, approved by aws, and made available for production welding by companies or individuals other than those. The easy way out is to select a filler metal that has matching strength, meaning that the minimum specified tensile strength of the filler metal matches that of the base metal.

The main responsibilities of a cwi is to make sure that welding operations are manufacturing products that comply with specified welding codes and. These formulas are meant to provide a value for weldability. Yet, less than 5% of the customers we consult with have at least a basic understanding of welding symbols. The ability to write and/or interpret welding symbols is essential for many welding industry professionals including welders, supervisors, cwis, welding engineers, estimators, qc personnel and more.

However, This Is Not Always The Best Option.

There are many different ce formulas, but the two most commonly used are those accepted by the american welding society and the international institute of welding. How many did you get correct? A career as a certified welding inspector (cwi) can be very rewarding. Weld size is affected by travel speed and welding procedures, specifically wire feed speed.

The Ability To Write And/Or Interpret Welding Symbols Is Essential For Many Welding Industry Professionals Including Welders, Supervisors, Cwis, Welding Engineers, Estimators, Qc Personnel And More.

Below are the answers to all 21 questions. The american welding society prohibits the use of short circuit transfer in prequalified welding procedures because of the high probability of lack of fusion. This certification, which is awarded by the american welding society, carries a lot of weight both nationally and internationally. Selecting the filler metal should not be a trivial matter.

The Easy Way Out Is To Select A Filler Metal That Has Matching Strength, Meaning That The Minimum Specified Tensile Strength Of The Filler Metal Matches That Of The Base Metal.

Typical shielding gases for short circuit transfer include 100% carbon dioxide and mixes containing up to 75% argon with the balance being carbon dioxide. Welding symbols communicate vital information to the welder. If you have worked with the american welding society codes, you have probably heard about standard welding procedures specifications (swpss). This is impossible to detect via weld inspection after welding is complete and very hard to detect while welding.

In Some Cases It May Be Beneficial To Use Undermatching Filler Metals.

It can be easily measured by the use of weld gages. These formulas are meant to provide a value for weldability. Yet, less than 5% of the customers we consult with have at least a basic understanding of welding symbols. There is a significant cost to obtain the […]

Weld size is affected by travel speed and welding procedures, specifically wire feed speed. Welding symbols communicate vital information to the welder. These formulas are meant to provide a value for weldability. The only difference between the two is that the aws formula includes silicon. How many did you get correct?